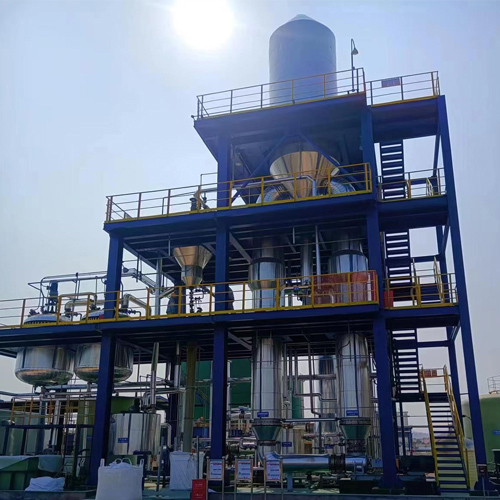

MVR evaporation crystallization system for ammonium chloride containing saline wastewater

On September 20, 2016, the MVR project for ammonium chloride saline wastewater, designed and constructed by Jiangsu Wodetop Thermal Technology Co., Ltd. for a certain environmental protection company in Guangzhou, successfully produced salt, and all operational indicators were better than the design indicators.

This project is a zero discharge project developed independently by the R&D personnel of Wardtop Company, combining years of production practice experience and adopting multiple patented technologies of the company, which can fully achieve salt extraction from high salt and high COD wastewater. The project enterprise was founded in Guangzhou Science City in 2007, specializing in industrial waste treatment and comprehensive utilization of resources. The "Guangzhou Development Zone Industrial Waste Comprehensive Utilization Base" project constructed by it has been included in the national "Environmental Protection and Resource Conservation 2011 Central Budget Investment Project". The annual treatment and utilization of various types of industrial hazardous waste will reach 109000 tons. The incoming wastewater of this project has a high organic content and complex composition, with a salt content (ammonium chloride) of over 120000 mg/L, making it a typical difficult to treat wastewater. This project adopts a combination of pre-treatment and MVR technology. Firstly, the COD of the material is effectively reduced through pre-treatment. Then, using the MVR low-temperature evaporation crystallization process, the salt (ammonium chloride) in the product is effectively recovered, and the product quality meets industrial grade requirements. The design of the entire resource utilization of saline waste liquid is reasonable, with leading technology and application level, safety and environmental protection, and meets the requirements of clean production. It provides a good demonstration technology source for completely solving environmental problems in domestic electroplating wastewater, which is at the leading level in China. It is another effective way to implement a circular economy strategy and transform and upgrade enterprises.