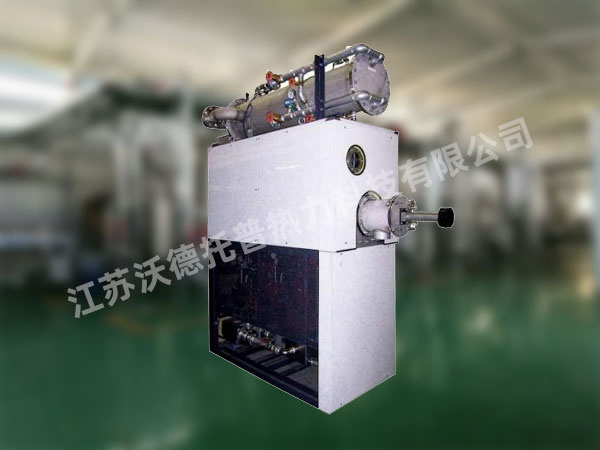

Vacuum evaporation drying device WDZL-150

This device is a device that distills and concentrates the fermented and precipitated waste liquid of rice wine under reduced pressure, allowing it to minimize (dry) the amount to the greatest extent possible.

At present, for the treatment of wastewater and waste liquid with high water content, the general approach is to add a certain amount of chemicals, treat them with activated sludge, and discharge them according to the discharge standards. The residue is treated by the mechanical force of a filter press to a moisture content of 60-80%, and then handed over to a professional company for treatment as industrial waste. The vacuum distillation method was used to reduce the moisture content of the residue to a few percent (less than 10%), establishing a closed system for the reuse of recycled water and a system for reducing industrial waste. As is well known, the air is thin, and high mountains at higher altitudes can easily boil water, and heating it at lower temperatures compared to land can make it boil.

This is because low air pressure reduces the boiling point of water, making it easier for water to boil. Similarly, when a container is depressurized to a vacuum (about -0.1MPa), water will boil at around 50 ℃. The device that applies this common principle to distillation, dehydration, concentration, or drying until solidification is called a vacuum evaporation drying device.

The typical wastewater treatment equipment is expensive and occupies a large area of very complex equipment. It is common to treat waste liquid and rice wine fermentation precipitation waste liquid as industrial waste. In addition, even most companies with treatment equipment only use dewatering machines to press the sludge into the mud cake and hand it over to the outside for treatment. Filter press, screw filter press, centrifugal dewatering machine, etc., due to the use of pressure, heating and other dewatering methods, the treatment effect is limited. The water content after treatment reaches about 60%. If the equipment becomes old and the effect decreases, the water content will reach about 70-80%. In addition, the cost of treatment will also increase due to the need to replace the filter cloth.

Compared with existing dehydration and concentration methods, this device has simpler equipment and lower operating components. After treatment, the residue can be dried to a moisture content of only about 10%. In addition, the water evaporated from the raw water is condensed and liquefied using a condenser, without producing harmful gases.